The Rise of Soft Robotics: How It's Revolutionizing Automation

In an age where industries demand faster, more adaptable, and cost-efficient solutions, traditional rigid robotic systems are reaching their limits. The rigidity that once provided precision now hampers flexibility, especially in environments that require delicate handling, quick adaptability, and safety. Enter soft robotics—a game-changing technology that mimics the dexterity and adaptability of human hands, while transforming automation across various industries.

What is Soft Robotics?

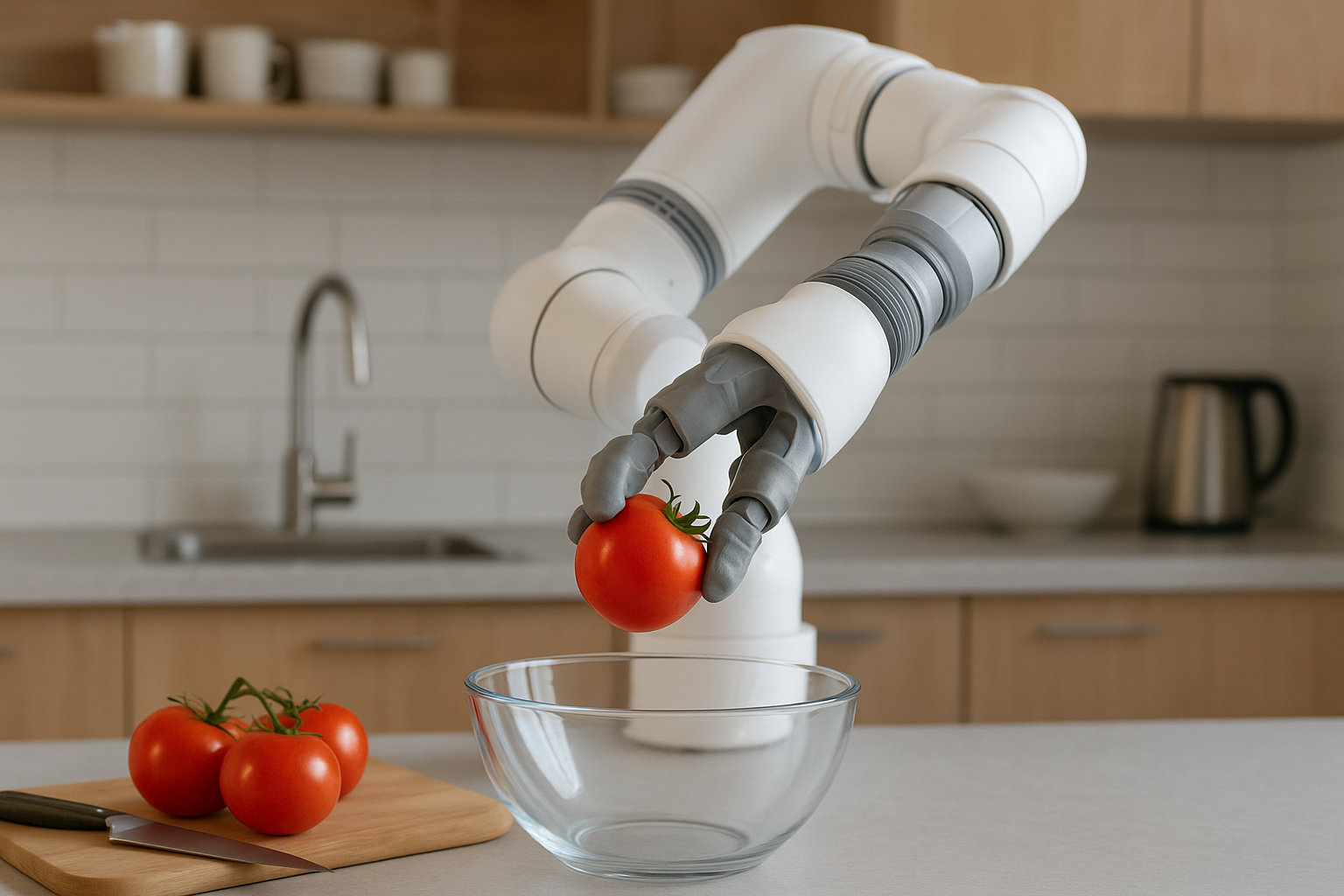

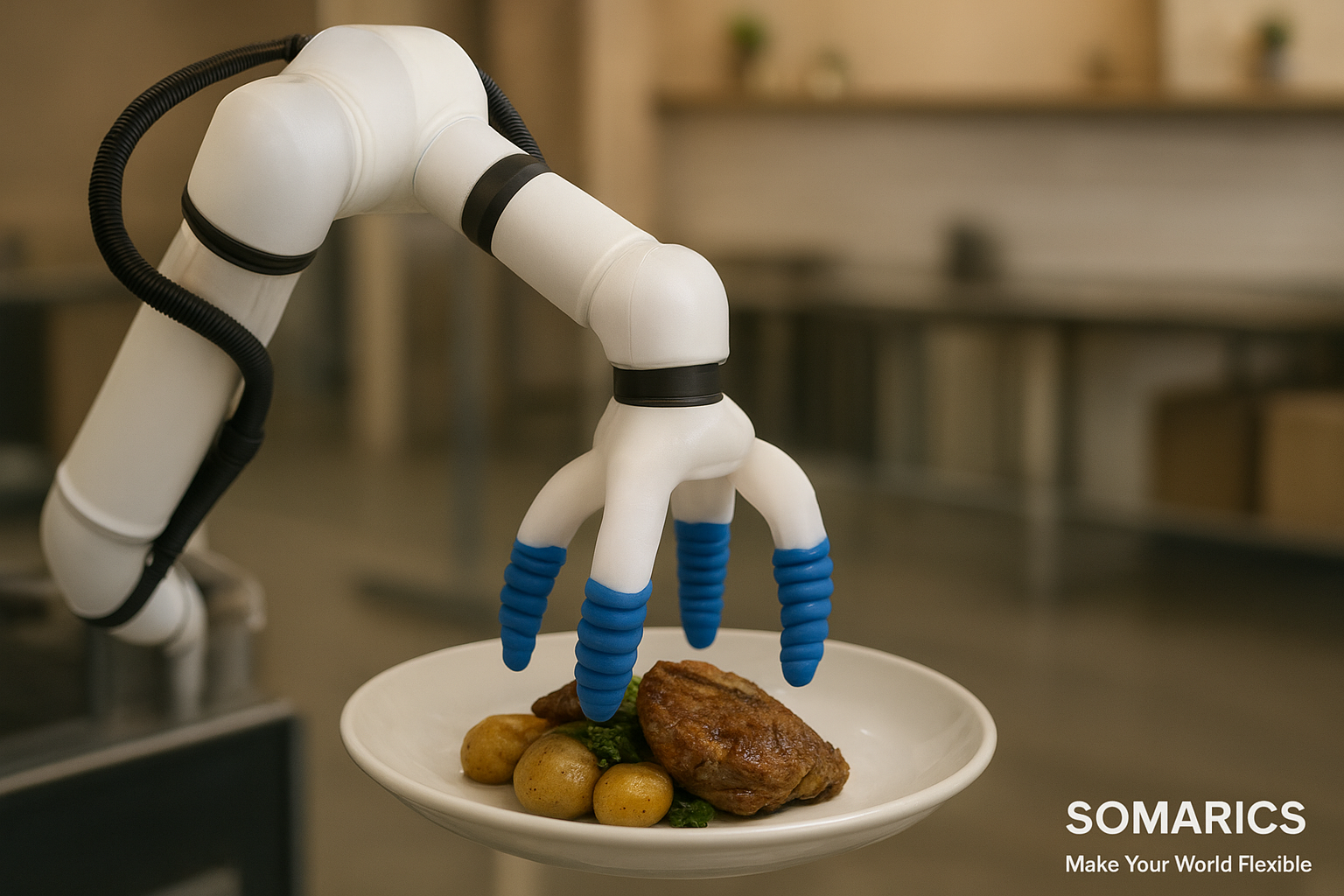

Soft robotics is an innovative branch of robotics that breaks away from the traditional use of rigid materials and designs. Instead, it focuses on flexible, compliant materials—often inspired by biological systems—that can deform, adapt, and interact safely with their surroundings. Unlike conventional robots that rely on precise and often restrictive programming, soft robots excel in environments where variability, complexity, and unpredictability reign. The beauty of these systems is their ability to conform to the object or environment they are handling, making them ideal for sensitive tasks in industries like food processing, healthcare, and electronics.

By mimicking the gentle touch and adaptability of human hands, soft robotics presents a significant leap forward in automation. But what exactly sets it apart? Let’s delve into the key advantages of soft robotics that are making it a top choice for the modern industrial landscape.

The Key Benefits of Soft Robotics

1. Adaptability and Flexibility

One of the most significant advantages of soft robotics is its inherent adaptability. Unlike traditional robots that need constant reprogramming and adjustment when confronted with new tasks, soft robots can easily handle a wide range of objects—regardless of shape, size, or delicacy—without the need for extensive retooling. This makes them ideal for industries that experience high variability in their production processes. From assembling intricate electronic components to picking fragile fruits in an agricultural setting, soft robots offer a level of flexibility that rigid robots simply cannot match.

2. Safety in Collaborative Environments

Safety is paramount in any industry, particularly when robots and humans work side-by-side. The compliant materials used in soft robotics ensure that these machines are much safer to work with compared to their rigid counterparts. In the event of accidental contact with a human, soft robots are designed to absorb the impact, minimizing the risk of injury. This ability to safely coexist with human workers—often referred to as “cobots”—opens up new possibilities for collaborative environments, where robots assist workers in tasks rather than completely replacing them.

3. Delicate Handling Capabilities

Industries that deal with fragile or delicate objects, such as pharmaceuticals, electronics, and food processing, benefit immensely from soft robotics. Traditional robots, which are designed for strength and precision, can easily damage fragile items. Soft robots, on the other hand, can handle items as delicate as fruits, medical capsules, or microchips without causing harm. This not only reduces waste but also increases the overall quality and yield of production, saving companies time and money.

4. Versatility Across Various Environments

Soft robots can function in a wide range of environments, from cleanrooms to rugged outdoor landscapes. Their versatility makes them ideal for industries as varied as manufacturing, healthcare, agriculture, and logistics. For instance, in search and rescue missions, soft robots can navigate confined and unstable spaces, making them invaluable in emergency situations. Their flexibility allows them to perform tasks that would be difficult or impossible for traditional robots, such as navigating through rubble to locate survivors after a disaster.

5. Cost Efficiency and Reduced Downtime

Soft robots’ ability to adapt quickly to new tasks and environments reduces the need for constant reprogramming, retooling, and system overhauls. This means less downtime and higher productivity. Additionally, their gentle handling capabilities minimize waste, further cutting costs associated with damaged products. For businesses focused on lean manufacturing and optimizing resources, soft robotics presents an efficient, cost-saving alternative to traditional automation systems.

Real-World Applications of Soft Robotics

Soft robotics is not just a theoretical advancement; it’s already being implemented across a variety of industries. The flexibility, adaptability, and safety of soft robots make them particularly useful in these key sectors:

1. Manufacturing

In industries like electronics, automotive, and aerospace, precision and adaptability are critical. Soft robots can perform tasks such as assembly, packaging, and quality control with greater care and flexibility than their rigid counterparts. Their ability to handle delicate components while adapting to different product variations makes them invaluable in fast-paced manufacturing environments where product lines are constantly changing.

2. Healthcare

Perhaps one of the most exciting applications of soft robotics is in the field of healthcare. Soft robots are already being used in delicate surgical procedures, rehabilitation, and prosthetics. In surgery, soft robotic tools provide surgeons with the precision needed for minimally invasive operations, while reducing the risk of complications. In prosthetics, soft robots are enabling the development of highly dexterous artificial limbs that offer users greater mobility and functionality than ever before. Soft robotics is also making strides in rehabilitation, where robotic exoskeletons help patients regain movement after injuries.

3. Logistics and Warehousing

The demand for flexible, automated solutions in logistics and warehousing is on the rise, and soft robotics is meeting this need. Soft robots can perform tasks such as order picking, material handling, and packaging, handling items of varying shapes and sizes without damaging them. This flexibility is particularly valuable in industries like e-commerce, where product types can vary greatly and speed is crucial.

4. Agriculture

In the field of AgriTech, soft robots are transforming the way crops are harvested. With the ability to gently handle delicate fruits and vegetables, soft robotic harvesters reduce damage and waste, leading to higher yields and more efficient operations. These robots can also operate in a variety of environmental conditions, making them ideal for both indoor farming and large-scale outdoor agricultural operations. As the demand for food increases, soft robotics offers a scalable solution that can help meet global agricultural needs.

5. Search and Rescue

Soft robots excel in environments that are too dangerous or unpredictable for humans or traditional robots. In disaster areas, they can navigate through rubble, tight spaces, or collapsed buildings, helping locate survivors and assist in rescue efforts. Their flexibility and adaptability make them ideal for tasks that require both precision and robustness in the face of uncertainty.

Challenges and the Future of Soft Robotics

While the potential for soft robotics is vast, the field is not without its challenges. Developing durable, reliable soft materials that can withstand harsh conditions is one of the key obstacles researchers are working to overcome. Additionally, creating advanced control systems that allow soft robots to perform complex tasks autonomously remains a significant hurdle.

However, as research and development progress, the integration of soft robotics with artificial intelligence (AI) and machine learning is expected to enhance their capabilities. This combination will allow soft robots to learn from their environment, making them even more adaptable and efficient over time. As these technologies mature, we can expect to see soft robots taking on more complex and diverse roles in industries ranging from manufacturing to space exploration.